Wednesday, May 31, 2006

BMC Airboxes have arrived...

Unfortunately, I'm waiting for the some hose fittings from Forge Motorsport in the UK so that I can fit them and since they've only sent them today then I'm probably going to have to wait until next weekend before I can fit them.

Hopefully, good things come to those who wait...

Monday, May 29, 2006

BMC DIA airbox

I took some measurements from the car this weekend. Here's what i need:

- x2 BMC DIA airboxes with 70mm outlets (I need to confirm that these are 140mm length since there's not a lot of space!).

- x2 70mm diameter flexible ducting lengths.

- x2 crossovers from 70mm to 50mm (these need to be stainless steel or aluminium... they're going to be located close to the turbos so need to be able to cope with the heat).

- x2 15mm filters for the oil vapour recovery system.

- x2 15mm 90 deg elbows (since the plug in the head cover are 90 deg and i'm not certain that i can pull these and replace them with straight plugs).

- x1 short length of 15mm silicon hose (to connect the small filters to the plug on the head cover... 100mm of hose should be sufficient, which i'll cut to fit).

- x2 support brackets (if not included in kit).

- x4 clamps for 15mm hose.

- x4 70mm clamps (plus 4 if i require additional 70mm elbows and connectors).

I'll utilise the existing 50mm 45 deg elbow to connect the 70x50mm corssover to the compressor inlet. I need to verify that I'll be able to bend the flexible hose through 90 deg within a length of 110mm, otherwise i'll need a 70mm 90 deg elbow and 70mm stainless steel/aluminium connector between the airbox and the flexible hose.

I'm placing the order with Auto Pro Sport in the Netherlands... I just need to get a quote off them, since I'm working on a budget!

So, it's confirmed that the inlet piping is indeed 50mm diameter, which in my mind is far too small upstream of the compressor. Downstream of the compressor this is acceptable, since the air is compressed and therefore the flowrate here is much less (about half). Moving to 70mm piping upstream of the compressor should give a nice balanced system, with the air velocity equal on both sides of the compressor.

The only way to test this is on the dyno of course... once I've order the parts and fitted them then I'll take the car along to Rica and get it remapped... and of course post the new dyno results.

Saturday, May 27, 2006

Another Maserati Ghibli blog!

Fantastic... someone else to share some idea with...

Thursday, May 25, 2006

Improved breathing for the Ghibli

Having seen my dyno charts and then looking at Modena Performance's torque and power figures for their tunes Ghiblis, it appears that my Ghibli is being restricted on air flow which is capping the performance of the engine. My attentions have been focused on the exhaust side of the engine and problems with the catalyst, but Jarle seems convinced that the problem lies on the inlet side.

So I've been doing a bit of research today, looking at air filters and boxes and stumbled across a new product from BMC that looks interesting. I've always found the air boxes amusingly small on the Ghibli, but this kind of makes sense when you consider there's two of them. I've also always found the fact that there's now decent route for air to flow from the front of the car into the intake system a bit strange on such a high powered car. But to be honest, there's not really an awful lot of space to stick anything exotic in. What's also a bit odd is the dimension of the inlet piping to the turbo compressor. Although it starts off at a pretty healthy looking diamter as it leaves the air box, it appears to rapidly constrict down to a dimater that looks to be in the region of 50 mm? Have a look at the picture below and you'll see what I mean.

From talking with Jarle, he seems pretty adamant that once you start increasing the power output on the Ghibli, the inlet side of the engine (filter, piping and inlet manifold) quickly constrain performance. He might well be on to something... I'll have to do some calculations to determine the pressure drop across the inlet piping from the air box to the compressor, but if you just look at the increase in area going from 50 mm to 70mm diamer, it almost doubles! If you also factor in the increased efficiency of say, a cone type filter versus the OEM filter, it's certainly not going to harm performance increasing the capacity of the intake system.

If you could also get some dynamic charging effect by directing cold air from the front of the car into the intake system, you could improve performance in further, but I've not been able to figure out an easy way of doing this on the Ghibli (although removing the plastic housing around the headlights like this guy has below would certainly help (see page 79 on Enrico's site for more details)).

I've always been put off cone filters by the fact that they're prone to suck up hot air from the engine bay when driving at low speeds (which in todays world is most of the time!) which effect both performance and engine longevity. I've therefore been looking for a replacement air box, to shield the air flow from heat as much as possible. I've thought about an itg Maxogen airbox, which in principle is an ideal replacement for the OEM airbox given the orientation of flow in and out of the unit. However, it's a bit too big for the Ghibli and given that you can't easily run a hose from the front of the airbox to the front of the car, it's function is a bit wasted, making the value proposition for this unit (remember you need two of them at about €250 each!) not very positive.

I've also been very tempted by the BMC Carbon Dynamic Airbox. However, as for the itg unit, the value proposition for this unit is not great for the Ghibli by virtue of the fact that it's dificult to route the flexible ducting from the front of the airbox to the front of the car.

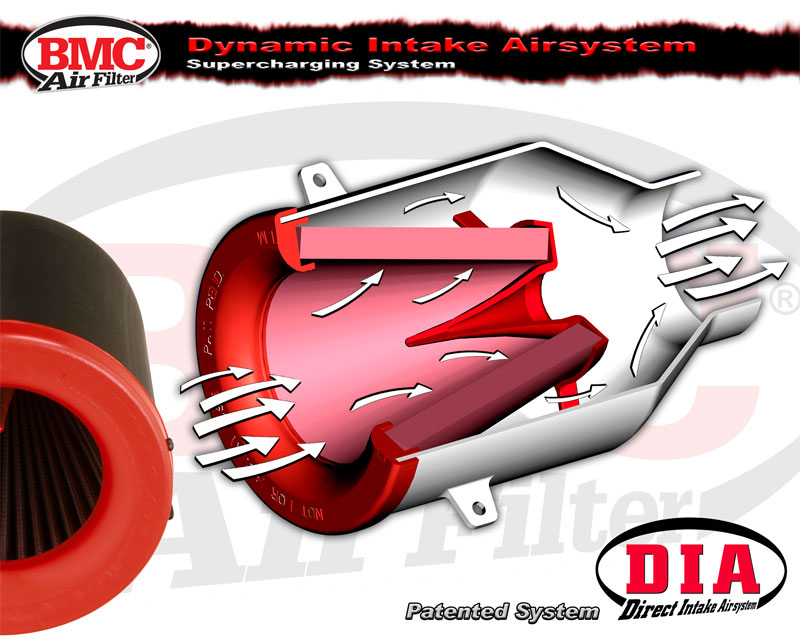

Then I stumbled on the new BMC Dynamic Intake Airsystem, for which I found a nice picture on the Dutch BMC distributors website pictured on the right. This is supposed to be the little brother of the BMC CDA above, made from cheaper materials and hence selling at a cheaper price. But given that it can be run withough the inlet ducting, it could just be perfect for the Ghibli, particularly if the plastic housing around the headlights is removed as in the picture above.

Then I stumbled on the new BMC Dynamic Intake Airsystem, for which I found a nice picture on the Dutch BMC distributors website pictured on the right. This is supposed to be the little brother of the BMC CDA above, made from cheaper materials and hence selling at a cheaper price. But given that it can be run withough the inlet ducting, it could just be perfect for the Ghibli, particularly if the plastic housing around the headlights is removed as in the picture above.So, time to do some sums. Using Bernoulli's equation (see eFunda for some background), good old Microsoft Excel and a bit of logical thinking, I come up with the following:

My Ghibli has a 2 liter engine and has a rev limit of 7200 rpm. I'll assume the volumetric efficiency of the engine is 90%. The engine inlet pressure is about 1.2 bar and I'll assume that the inlet temperature is about 70 deg C. Air only flows into the engine half the time per revolution of the crankshaft, so to determine the flowrate of 1.2 bar air into the engine, multiply everything together and divide it by two to get 6.48 m3/min or 0.108 m3/sec. This is air at 1.2 bar and 70 deg C, but I'm interested in air flowing through the inlet ducting upstream of the compressor. I'll assume that the air here is at atmospheric pressure and temperature, so 1 atm and 20 deg C. Since PVT = constant, the volume of air on the inlet side of the compressor is about 0.936 m3/sec assuming 90% volumetric efficiency. Since the Ghibli has two inlet conduits, this volume must be halved to give 0.468 m3/sec.

I'm assuming that the inlet piping from the airbox to the compressor inlet on the Ghibli is 5 cm diameter, but I still need to measure and confirm this. If this is the case, then the velocity of the air flowing through the piping is 238 m/sec. Considering that the speed of sound is about 340 m/sec (at which speed all sorts of funny effects start to occur), this seems to be an unneccessarily high velocity for the inlet system? The air flow is undoubtedly turbulent at this rate (this is verified by calculating the Reynold's number). You can get all the air properties also from eFunda.

Next thing is to determine the pressure drop across the inlet piping. To do this requires a bit of Bernoulli. Assuming a friction factor of about 0.02, that the compressor inlet is 30 cm below the airbox and that the length of inlet piping is 50 cm, I calculate that there's about a 0.07 bar pressure drop across the inlet ducting. Dosen't sound like much, but it means that the turbo is having to do work just to suck air into the compressor. If I now calculate the pressure drop for a 7 cm diameter intake pipe, the pressure drop is reduced to about 0.01 bar.

So what does this mean? Well, looks like I'm loosing about 6% flowrate of air due to the choking effect of my current intake piping over increasing the diameter to 7 cm. Since power is directly proportional to the volume of air, this means I could increase the power output of the Ghibli by 6% just by increasing the diameter of the ducting. So that's a 20 hp increase over the current 328 hp, taking it up to just shy of 350 hp.

Looks like I'll be ordering some new stuff pretty soon!

Monday, May 22, 2006

More Rica results...

The first page shows before and after changing out the boost controller. After the first visit, the car was under performing due to an OEM boost control solenoid failure. This lead to the curve dated 12.10.2004 and is essentially the power with 0.7 bar.

Once the boost control solenoid was changed out (with a new OEM unit), the curve labelled 21.10.2004 was produced. The second page shows just the 2nd curve.

You'll notice that the torque and power ramp up significantly later than Maserati claim. This could just be my car, but I doubt it since my car is low mileage and everything's been well looked after.

The third page shows dyno results for my post 3200 GT turbos, but I'm positive that it's performing way below what it should be, due to the suspected blocked up catalysts. Hopefully, later this year I'll place an order for a new exhaust front section and finally get to the bottom of this. My reason for suspecting this is, just after I fitted the new turbos I got a dyno test done which showed 306 hp with only 0.7 bar (unfortunately I didn't get a copy of this one). So I know the potential is there for some increased performance with the 3200 GT turbos. At present, I'm getting 328 hp with a little over 1.2 bar and I'm a bit down on torque. Some of this can be explained by the fact that the car is running slightly rich, but I'm positive there's a restriction in the exhaust side.

I'm also currently running a Turbosmart E-Boost 2 electronic boost controller to control the inlet pressure. Another reason why I think there's something odd going on, which again may point to a restriction in the exhaust side, is that I can't get the boost pressure to spike. Despite ramping up the gain on the controller to near full, the boost pressure just won't overshoot the set pressure. I don't believe the turbos are so large that they can't spike the pressure, so I can only think that somewhere there's a restriction.

Anyway, these are just my thoughts. I'd be really interested to hear if anyone else has tried playing with a boost controller and whether they manage to get the boost pressure to spike OK.

Rica chip tuning a Maserati Ghibli

I did indeed get my Ghibli chipped with Rica. They reprogrammed the chip rather than installing a new one (although they did upgrade the timing chip since they complained that the standard one was too slow).

I've generally had a good experience with them. They're not the cheapest, but included in the price I get a lifetime of service; every time I change something on the car (like fit a new exhaust for example) then they remap the chip free of charge. I even get a "free" dyno test every time they do something.

They tailored the upgrade specifically for the car... it's not an "off-the-shelf" job. Every time they change something they test it on the dyno and using a lambda sensor they check to see if everything's working to plan.

The first time I took the car to them, they increased the rev limit to about 7200 rpm. The car runs absolutely fine at these revs, with not a hint of the engine being over stressed or unballanced. As a result, the engine output increased from the standard 306 hp to 327 hp. It's always an eye opener taking the car on the dyno, since it invariably shows up how the car is running. When I first took it along, it uncovered that the car was only producing 270 hp. After a short bit of investigating, I found out that the boost controller on the car had stopped working and was running in fail safe mode, only producing about 0.7 bar boost pressure. It wasn't until the boost controller was replaced that the car produced 327 hp with about 1.2 bar inlet pressure.

Bear in mind that I've only had dealings with Rica in Wateringen in the Netherlands. You really depend on the skill of the chip tuner and this of course varies from place to place. The guys where I take my car have had some previous experience with Maseratis and seem to think the electrical system on the Ghibli is rather archaic. Hence the free chip upgrade they gave me.

One thing that I am sceptical about is the recent experience I had with my exhaust. It appears that my car was running for some time in open loop mode due to a faulty lambda sensor connection. It took me a while to track down the problem to this and when I eventually did, I was very suprised that the engine's management system hadn't triggered the "check engine" light on the dash. Anyway, I suspect that running the car rich has plugged up my catalysts. I'm also now a bit weary of installing new catalysts since I don't trust the engine management system to tell me if there's any problems with the fuel mixture. So the only way around this is to fix the engine management system (which isn't going to happen... there's very few people who have the know how to do this), piggy back my own diagnostic system (which is maybe what I'll do, since I plan some future upgrade) or replace the exhaust with straight through pipes and risk running into problems with the police. Anyway, the reason why I say this is because I suspect that rica may have had something to do with the management system not registering the problem with the lambda sensor (although they swear that they don't touch any of the error flagging bits of software, only the fuel and timing maps).

In short... I wouldn't hesitate in taking my car back to Rica, indeed I toyed with the idea of taking my wife's Volvo V50 to them (especially since they offered me a discount for being a loyal customer) but my wife made it quite clear that my car was for playing with, not hers! Indeed, Rica have a contract with the Volvo dealership in the Netherlands... I believe that Rica are responsible for the difference in power between the standard 2.4 model and the 2.4i model... the former is 140 hp and the later is 170 hp and the only difference is the fuel and timing maps. If I'd taken my wife's car to them they would have given me 180 hp (from the car's standard 140 hp) and Volvo would not know the car was chipped. I've actually been at their workshop when a mechanic from Volvo has bought along a customer's car to get it chipped. Incidentally, Volvo charge about a 70% mark up on getting the car chipped directly with Rica!

Aquamisting a Maserati Ghibli

The idea is to sufficiently cool the charge air going into the engine so that the boost pressure can be safely increased in order to produce more power. The standard pressure at full boost on the Ghibli is about 1.2 bar. I'm currently running a little more than this with the help of the Turbosmart E-Boost 2 electronic boost controller. Using this boost controller, it's possible to increase the boost pressure to as much as 2.75 bar, but this would produce so much heat and pressure that the engine would quickly detonate. However, with sufficient cooling of the charge air, the engine should be able to comfortable operate with 1.4 bar, which would be the target inlet pressure after installing the water injection system.

The idea is to sufficiently cool the charge air going into the engine so that the boost pressure can be safely increased in order to produce more power. The standard pressure at full boost on the Ghibli is about 1.2 bar. I'm currently running a little more than this with the help of the Turbosmart E-Boost 2 electronic boost controller. Using this boost controller, it's possible to increase the boost pressure to as much as 2.75 bar, but this would produce so much heat and pressure that the engine would quickly detonate. However, with sufficient cooling of the charge air, the engine should be able to comfortable operate with 1.4 bar, which would be the target inlet pressure after installing the water injection system.The water injection system of choice is ERL's Aquamist 2d system pictured above. A schematic of this system is pictured below.

What's missing from this system is a water storage tank; I still don't understand why ERL don't offer a purpose designed water tank for this system, although I understand that it's assumed that the system will be tied into the car's windscreen washer tank, with the low pressure pump that supplies water to the washer nozzle acting as a primer pump for the high pressure water injection pump. There's a couple of reasons why this setup isn't ideal for the Ghibli. The main one is that the battery on the Ghibli is located in the boot of the car. Since the water injection pump draws a fair amount of current, it ideally needs to be located pretty close to the battery, otherwise some pretty thick gauge wire needs to be run from the boot of the car to the engine bay, sufficient to accomodate the required current supply to the high pressure pump. I've had some bad experience running cable between the front and the back of the car... I used to have a VW Corrado G60 a while back and the unscrupulous previous owner had left some wiring exposed in the boot, presumably from a large bass speaker that he'd installed. One day I was driving down the motorway when the car filled up with smoke... the exposed wires had formed a circuit, resulting in the wire insulation burning. Fortunately I managed to pull onto the hard shoulder and sort the problem out, but it's not an experience I'd like to repeat any time soon. I can't think of the second reason off the top of my head, but bottom line is that I'd locate the pump in the boot.

Having determined that I want the pump in the boot, that means sourcing a dedicated water tank to supply the water. Since I want to minimise the amount of hose being routed around that car and I'd prefer a reliable gravity feed between the water tank and the pump (to increase reliability and robustness of the system), the water tank ideally needs to be located in close proximity to the pump. This implies mounting the pump in the boot next to the pump. After searching around for decent water tanks (which is more difficult than it sounds) I've come to the conclusion that a modified version of the Forge fuel tank pictured here would be a suitable solution. This is a 2 gallon tank, which is about 7.6 liters. The Ghibli fuel tank holds about 70 liters (might be 80? can't remember off the top of my head). Therefore, the water tank is about 10% of the fuel volume, which is a good ratio if you're going to be driving with the Aquamist system running all the time since it means worse case you need to fill up the water tank when you fill up the fuel tank. I don't envisage driving this hard though, so the water should last a few fuel top ups.

Having determined that I want the pump in the boot, that means sourcing a dedicated water tank to supply the water. Since I want to minimise the amount of hose being routed around that car and I'd prefer a reliable gravity feed between the water tank and the pump (to increase reliability and robustness of the system), the water tank ideally needs to be located in close proximity to the pump. This implies mounting the pump in the boot next to the pump. After searching around for decent water tanks (which is more difficult than it sounds) I've come to the conclusion that a modified version of the Forge fuel tank pictured here would be a suitable solution. This is a 2 gallon tank, which is about 7.6 liters. The Ghibli fuel tank holds about 70 liters (might be 80? can't remember off the top of my head). Therefore, the water tank is about 10% of the fuel volume, which is a good ratio if you're going to be driving with the Aquamist system running all the time since it means worse case you need to fill up the water tank when you fill up the fuel tank. I don't envisage driving this hard though, so the water should last a few fuel top ups. The location of the ports would need modifying a bit; I'd want some lugs adding to it onto which I can fasten the ERL pump and I'd also want a fitting added so that I could install the low level safety switch pictured here. I'd probably get the Aquamist kit from Turbobits since the guy who runs this online shop owns a Maserati on which he's tinkered with the boost controller and installed a first generation Aquamist system which he's documented on his site here. He also sells lots of ancillary bits and bobs that would be required for the Ghibli install.

The location of the ports would need modifying a bit; I'd want some lugs adding to it onto which I can fasten the ERL pump and I'd also want a fitting added so that I could install the low level safety switch pictured here. I'd probably get the Aquamist kit from Turbobits since the guy who runs this online shop owns a Maserati on which he's tinkered with the boost controller and installed a first generation Aquamist system which he's documented on his site here. He also sells lots of ancillary bits and bobs that would be required for the Ghibli install. Having installed the pump and the tank in the boot of the Ghibli, I'd run a 6mm high pressure hose from the boot to the engine bay, probably running down the passenger side of the interior of the car and through a hole in the firewall. The nice thing about running a long length of hose from the pump to the nozzles is that the hose effectively acts as an anti-surge accumulator, negating the requirement for the item shown on the left; the hose will baloon slightly as the pressure increases inside it... the longer the hose, the greater the balooning volume, so a decent lengthed hose will dampen the pressure spikes of the system. Therefore, to utilise the hose as an anti-surge accumulator, the manifold would need to be located in the engine bay.

Having installed the pump and the tank in the boot of the Ghibli, I'd run a 6mm high pressure hose from the boot to the engine bay, probably running down the passenger side of the interior of the car and through a hole in the firewall. The nice thing about running a long length of hose from the pump to the nozzles is that the hose effectively acts as an anti-surge accumulator, negating the requirement for the item shown on the left; the hose will baloon slightly as the pressure increases inside it... the longer the hose, the greater the balooning volume, so a decent lengthed hose will dampen the pressure spikes of the system. Therefore, to utilise the hose as an anti-surge accumulator, the manifold would need to be located in the engine bay.Rather than utilise the adjustable pressure switch that is included in the Aquamist 2d kit, I'd utilise the E-Boost to activate the water injection system. The E-Boost can be programmed to activate outputs at user defined pressures and since the boost controller already monitors inlet pressure, there's no point installing an additional potential leak path to the boost system. So the output from the E-Boost would be connected to the Aquamist manifold and set it to crack open at, for example, 1.0 bar.

The nice thing about utilising the E-Boost unit is that it can also be tied into the low level trigger on the water tank. The E-Boost has the facility to operate in three distinct modes. Using it in conjunction with the Aquamist system would require two of these modes to be utilised. The first would be the fail safe mode. The low level switch would be set such that when there's no water in the tank, it returns a zero logic (hence acting as a fail safe in the event that there's loss of power to the Aquamist system). When the E-Boost receives a 0 logic state from the low level switch, it would switch to the default operating mode, running the standard 1.2 bar boost pressure on the assumption that no water is available for injection into the inlet system.

When there's sufficient water in the tank, the low level switch will return a logic state of 1 to the E-Boost. This logic state will switch the E-Boost to water injection mode and enable a boost pressure of 1.4 bar (for example). As an added safety feature, the blocked nozzle detection system of the Aquamist FiA2 controller will control a relay on the low level switch circuit. The relay will be normally open, necessitating that the FiA2 keep it closed under normal operating conditions and hence acting as a fail safe in the event that the Aquamist system looses power. If the FiA2 detects that there's no water flowing through the injection nozzles, then the relay will open and the E-Boost will switch to default mode, operating at 1.2 bar.

As you can see from the picture above, the Ghibli has two intercoolers and hence two inlet hoses that meet at a Y-piece at the throttle body. To get a good mixture of water and air, but also injecting as close to the plenum chamber as possible, I'd install two injection nozzles, one on each of the inlet "pipes" just upstream from the Y-piece. The shiny tube sections shown in the picture were manufactured to order from Forge motorsport in the UK and have the blow off valves welded directly onto them. I'd send these back to Forge and ask them to weld some additional material onto the tube and then drill and tap it at an appropriate size in order to install the nozzles. I'd locate the nozzles just downstream of the blow off valves in order to prevent water spray from being blow into the engine compartment.

In order to operate two nozzles, I'd require a Y-piece to be installed just downstream of the high speed valve included in the Aquamist kit. I'd want to locate this Y-piece as close as possible to the nozzles and make sure that the hose lengths from the Y-piece to the nozzles were of equal length. I'd also step down the hose size after the Y-piece to 4mm to help maintain the pressure between the manifold and the nozzle. After some communication with ERL via Turbobits, it appears that it's not necessary to run two high speed valves with two nozzles. If one nozzle blocks up, then more flow will pass through the remaining nozzle which should be sufficient to keep the charge cool. If the remaining nozzle then blocks up, the FiA2 module will detect it and send an error signal to the E-Boost to switch to fail safe mode.

So there you have it. That's the theory... just need to put it into practice. Can't see myself having time this year, but probably next year. Maybe Aquamist will have bought out a new system by then though!

Sunday, May 21, 2006

2nd Maserati Ghibli

Monday, May 08, 2006

Wheels on order...

The guys at Korst are a bit uncertain as to whether the tires I want will fit, but they're going to have some smaller ones available when they fit the wheels just in case. However, if this happens I might just take the larger tires and have the lip on the wheel arches rolled up. Just have to see once they arrive...

My wife and I are thinking of driving over to the UK later in the summer and doing a bit of a road tour... so that's good incentive to get everything sorted and working properly on the Ghibli in time, otherwise will have to make the journey in the Volvo, which won't be half as much fun! The missus is also talking about getting me a dog... there's no way that I'm sticking a dog on the back seat of the Ghibli, so it might be the Volvo after all.

Would be nice driving the Ghibli in the UK though... I don't believe the Dutch and the UK police forces have joined forces yet, which may mean continued immunity to speed cameras...???